UHMW-PE [PE1000:ultra high molecular weight polyethylene]

UHMW-PE sets the standard for engineered polymers with a unique combination of wear and corrosion resistance, low friction surface and impact strength. It is resistant to chemical attack and moisture absorption, and retains key physical properties to -30° C.

Main Characteristics:

- Very good wear and abrasion resistance

- High impact strength, even at low temperatures

- Excellent chemical resistance

- Low coefficient of friction

- Excellent

- Moderate mechanical strength, stiffness and creep resistance

Applications:

FOOD, BEVERAGE, BOTTLING and PACKAGING INDUSTRY

The excellent abrasion and chemical resistance in addition to the ability to absorb noise makes it ideal for applications such as:

– Star wheels and corner guides

– Chain and belt guides

– Idler sprockets

– Guide rails and rollers

– Bin and mixer linings

CONVEYING INDUSTRY

Today’s high speed conveyors demand surfaces with a low coefficient of friction combined with excellent impact and abrasion resistance. UHMW-PE is ideal for the following applications:

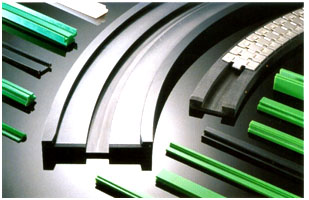

– Straight and curved tracks

– Wear strips and guide rails

– Rollers and roller sleeves

– Gears and sprockets

– Pillow blocks

UHMW-PE Wearstrips

UHMW-PE Wearstrips offers excellent sliding properties, lightweight material and FDA-approved for food contact. It is most commonly used as guides and rails in most conveyor systems.

UHMW-PE Wearstrips are available in a wide variety of profiles and can be extruded in continuous lengths. Custom profiles are also available upon request.