SEMITRON ESd

The Semitron ESd family of static dissipative products is designed for applications where electrical discharge in operation is a problem. They are commonly used for sensitive electronic components including: integrated circuits, hard disk and circuit boards. Semitron products are also an excellent choice for material handling applications, and components in high speed electronic printing and reproducing equipment.

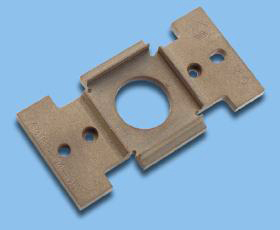

Semitron ESd 225 (Static Dissipative Acetal)

Semitron ESd 225 is ideal for fixturing used in the manufacturing of hard disk drives or for handling in process silicon water. It is tan in color.

- Surface resistivity: 1010 – 1012 Ω/sq.

- Thermal performance to 107°C

- Good wear resistance

Semitron ESd 410C (Static Dissipative PEI)

Semitron ESd 410c is ideal for handling integrated circuits through the test handler environment. It is black in color and opaque.

- Surface resistivity: 104 – 106 Ω/sq.

- Thermal performance to 210°C

- Low stress for tight tolerance machining

- High strength and stiffness

Semitron ESd 500 (Static Dissipative PTFE)

Reinforced with a proprietary synthetic mica, Semitron ESd 500 offers an excellent combination of low frictional properties and dimensional stability. Semitron ESd 500 should be considered wherever Teflon PTFE is used. It is ideal for applications where controlled bleed off of static charges is critical. It is white in color.

- Surface resistivity: 1010 – 1012 Ω/sq.

- Thermal performance to 260°C

- Thermally insulative

- Very low coefficient of friction

- Board chemical resistance

Semitron ESd 520HR (Static Disspative Machining Stock)

Semitron ESd 520HR has an industry first combination of electrostatic dissipation (ESd), high strength and heat resistance. This new ESd material is ideal for making nests, sockets and contactors for test equipment and other device handling components. The key features of 520HR are its unique ability to resist dielectric breakdown at high voltage (>100V). The graph below demonstrates the electrical performance of plastic materials commonly used in automated test handlers. Typical carbon fiber enchanced products become irreversibly more conductive when exposed to even moderate voltage.